Consumer Products

Our Services

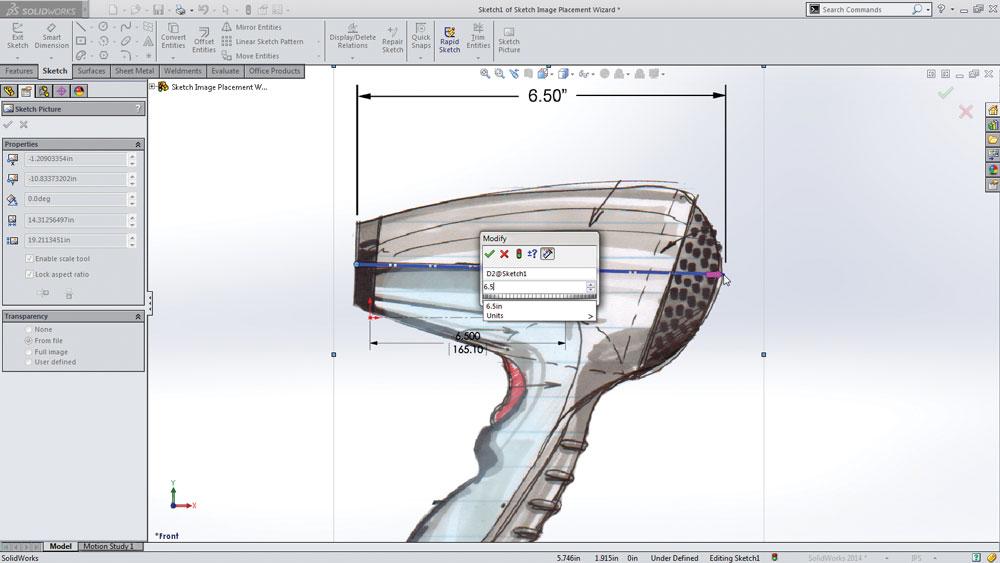

Computer-Aided Design & Manufacturing (CAD/CAM) for Consumer Product Testing Machines & Productions

🔹We design and optimize custom testing equipment to help manufacturers assess product performance, durability, and compliance with industry standards.

✅ 3D CAD modeling for consumer product testing machines

✅ Reverse engineering & design enhancement for existing testing equipment

✅ Technical documentation & manufacturing drawings for production

✅ Custom fixtures & tooling for testing processes

✅ Ergonomic and user-friendly design integration

🔹We support manufacturers in CNC programming and production optimization for consumer product testing machines.

✅ CNC toolpath optimization & G-code generation for machining precision components

✅ Virtual machining simulations to optimize cutting strategies and reduce waste

✅ Automated manufacturing workflow planning for testing machine production

✅ Material selection and manufacturability assessment

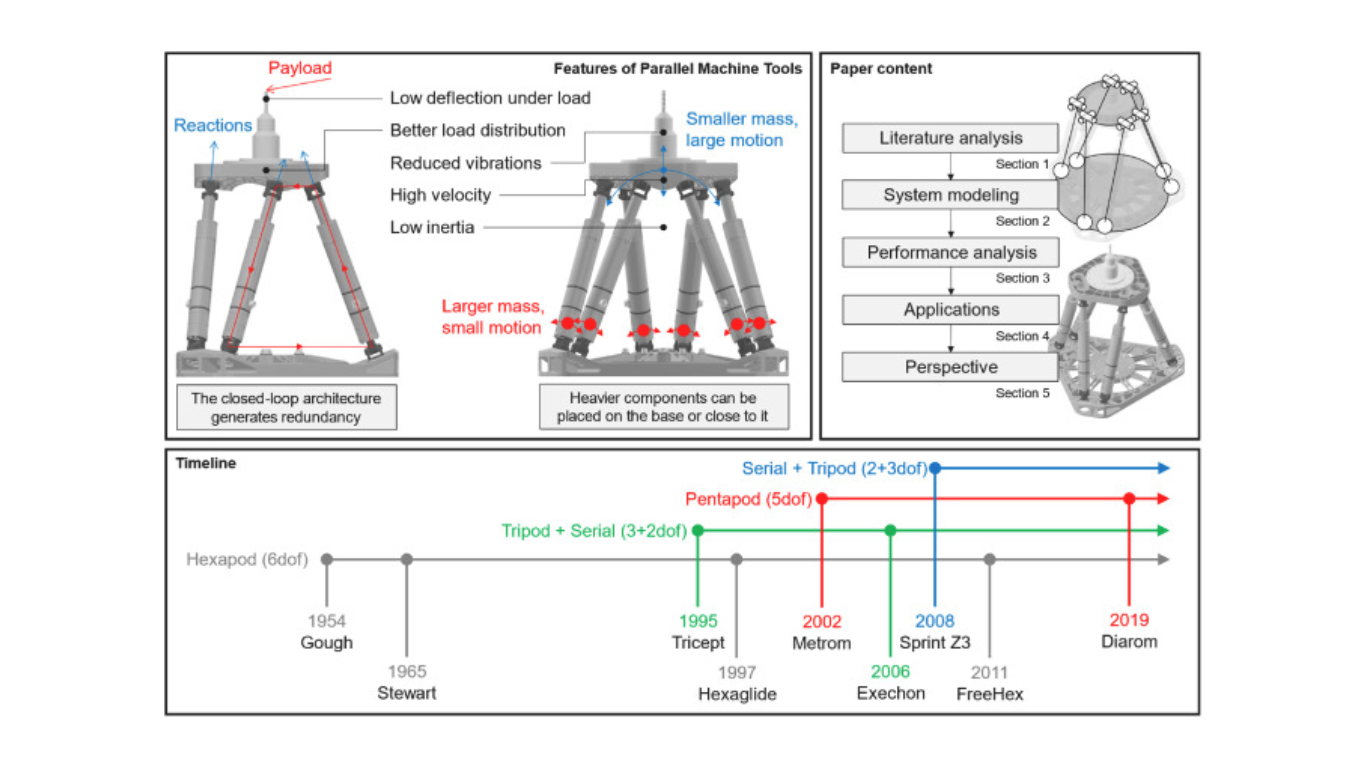

Computer-Aided Engineering (CAE) for Testing Equipment Performance

🔹CAE simulations ensure reliable, accurate, and high-performance testing machines that meet industry standards.

✅ Structural analysis for load-bearing components in testing machines

✅ Thermal & fluid flow analysis for temperature-sensitive testing environments

✅ Motion & kinematic analysis to validate machine operation efficiency

✅ Failure prediction & fatigue analysis to enhance equipment durability

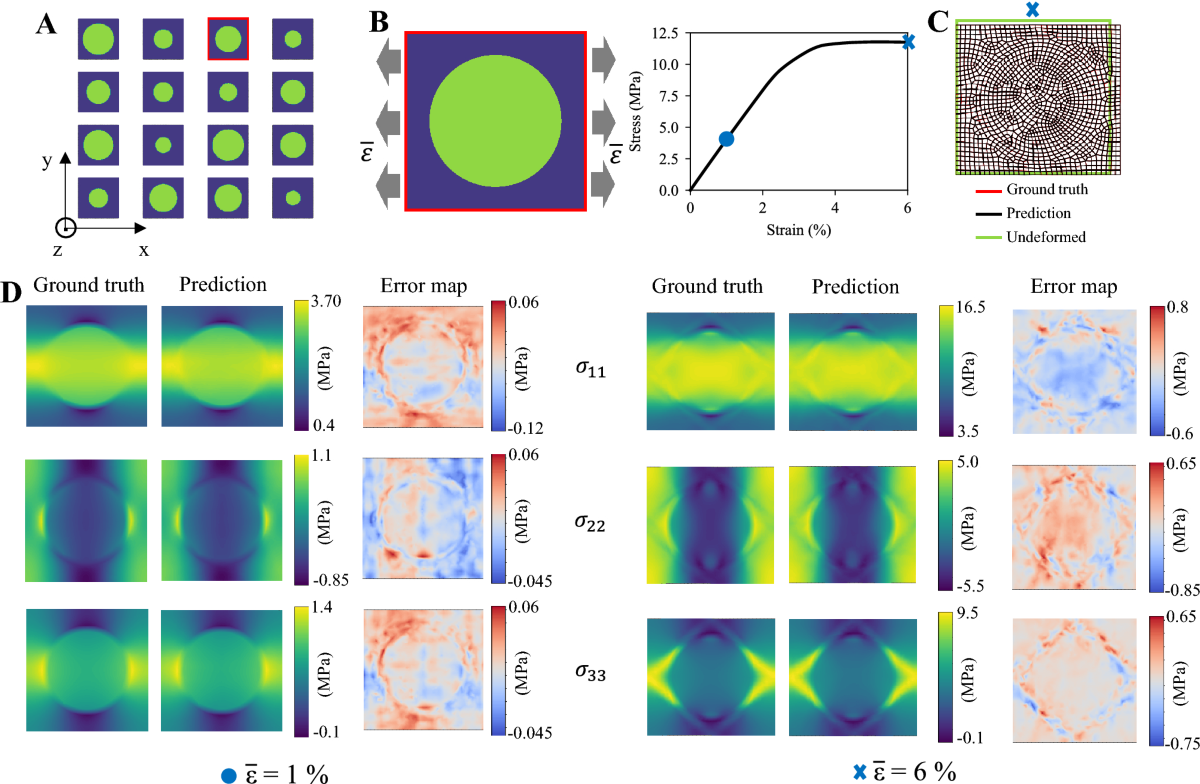

Finite Element Simulation (FEM/FEA) for Testing Equipment Validation

🔹We use FEM/FEA simulations to predict stress, strain, and material behavior under real-world conditions for testing machines.

✅ Structural integrity simulations for high-pressure and repetitive load applications

✅ Material behavior testing for long-term durability

✅ Impact and vibration analysis for high-speed testing equipment

✅ Thermal analysis for machines that test heat resistance in consumer products

Digital Mock-Up (DMU) for Virtual Machine Testing

🔹DMU allows manufacturers to simulate and validate testing machine performance before production, reducing costly errors.

✅ Virtual testing of product interactions within the machine

✅ Clash detection & interference analysis for testing mechanisms

✅ Motion simulation for automated testing procedures

✅ Digital twin technology for real-time remote monitoring & predictive maintenance