Industrial Equipment

Our Services

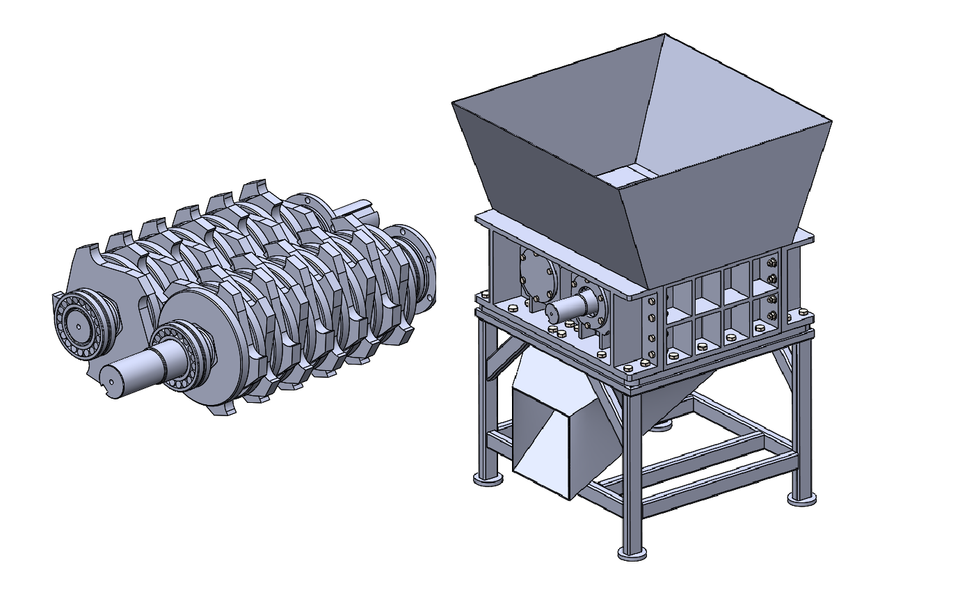

Computer-Aided Design & Manufacturing (CAD/CAM) for Industrial Equipment and Production

🔹We help manufacturers design, optimize, and document industrial machinery and components through advanced 3D modeling and technical drawings.

✅ 3D CAD modeling for heavy machinery, automation systems, and components

✅ Reverse engineering of existing equipment for upgrades and modifications

✅ Technical documentation and manufacturing drawings for production

✅ Design for manufacturability (DFM) and cost-effective production

✅ Custom machinery design and integration planning

🔹Tannari assists manufacturers in programming and optimizing CNC machining for industrial parts and equipment.

✅ CNC programming & toolpath optimization for efficient machining

✅ G-code generation & virtual machining simulations

✅ Fixture & tooling design for mass production efficiency

✅ Digital manufacturing workflow planning

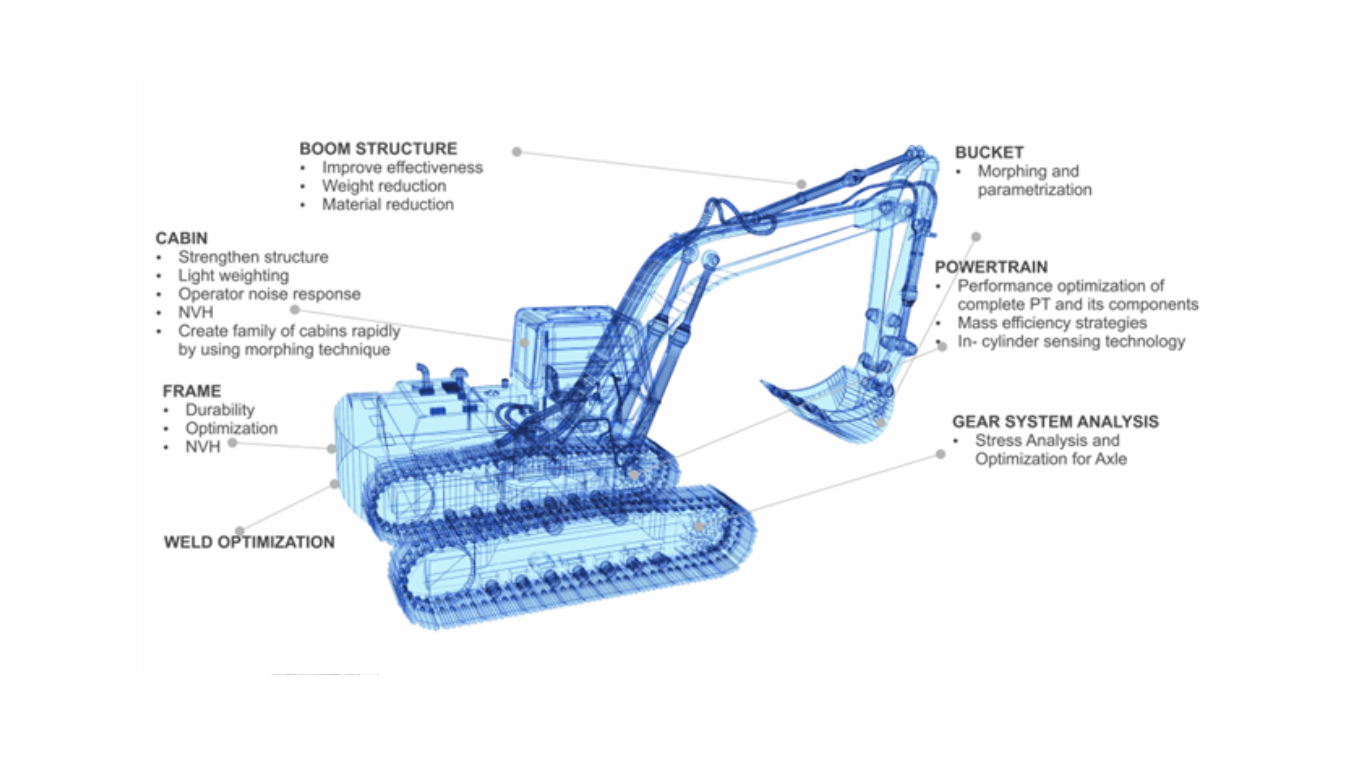

Computer-Aided Engineering (CAE) for Equipment Performance Optimization

🔹Our CAE simulations help manufacturers validate and optimize industrial equipment for durability, safety, and efficiency.

✅ Structural analysis for heavy equipment, robotic arms, and mechanical structures

✅ Thermal & fluid flow simulations for industrial cooling & heat dissipation

✅ Motion & kinematic analysis for mechanical linkages & moving parts

✅ Failure prediction & fatigue analysis to ensure longevity & reliability

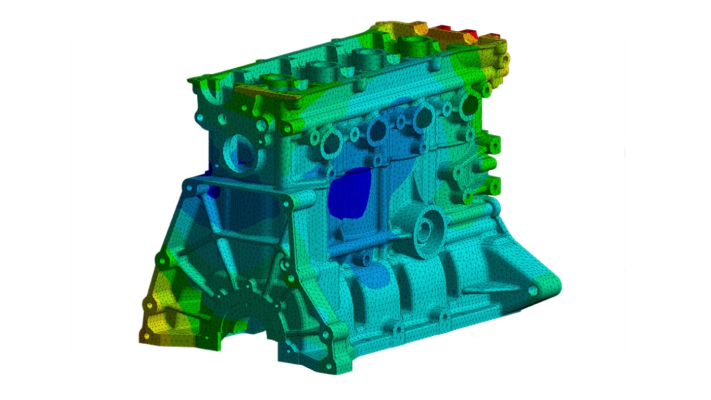

Finite Element Simulation (FEM/FEA)

🔹We use FEM/FEA techniques to predict stress, strain, and material behavior under operational conditions.

✅ Structural integrity testing for pressure vessels, machine frames, and automation systems

✅ Vibration & fatigue simulations for rotating and high-load components

✅ Material optimization & failure analysis for long-lasting performance

✅ Impact, thermal, and electromagnetic simulations for electrical & mechanical equipmen

Digital Mock-Up (DMU) for Virtual Prototyping & Testing

🔹DMU enables manufacturers to visualize and test full industrial assemblies virtually before production.

✅ Virtual assembly validation for machinery integration & design optimization

✅ Motion simulations & clash detection to prevent design conflicts

✅ Digital Twin solutions for predictive maintenance & real-time performance monitoring

✅ Interference detection for complex multi-component systems